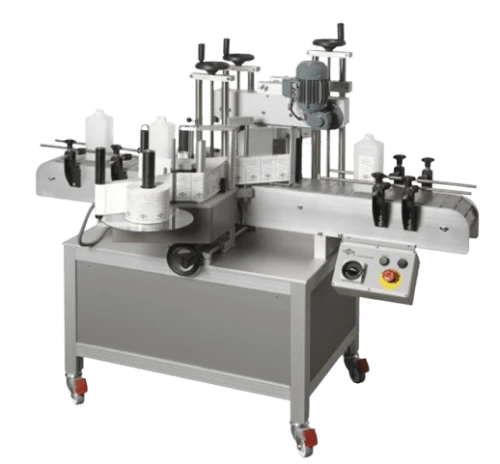

Tri Roller Labelling Machine

Tri-Roller – Precision Wraparound Labelling for Round Containers

The Tri-Roller is a high-performance automatic labelling system designed specifically for applying self-adhesive labels to cylindrical containers. It provides seamless accuracy and consistent repeatability.

Tri-Roller Labeller

Machine Features

Built for speed, precision, and flexibility, the Tri-Roller features a pneumatically powered separator and a rotating label application process for consistently high-quality results. Ideal for standalone use or integration into larger production environments.

Max Speed

Achieves up to 60 passes per minute depending on label and container

Accuracy

Rotating label application ensures precise alignment around the container

Fully Adjustable Conveyor

82mm+ width and 1.6m+ length, adjustable speeds to suit product requirements

Easy Adjustment

Change container diameters quickly with a finger screw and turn wheel for idle rollers

Modular Label Head Options

Available in 120mm, 200mm, 250mm & 300mm widths, left or right handed

Expandable Printing Options

Supports thermal inkjet and thermal transfer printers for coding and batch marking

Memory Settings

Store up to 25 programmable files for fast product changeovers

Power & Air Supply

220/240V AC, 50/60Hz, 600W; Clean compressed air, 6 bar max, 8 l/min

About the Machine

Why Choose the Tri-Roller?

- High-quality wraparound labelling for cylindrical products

- Pneumatic product separation ensures consistent single feed

- Easy-to-use adjustments for multiple container sizes

- Fully programmable memory for quick and accurate changeovers

- Seamless integration with printers, sensors, and coding equipment

- Suitable for standalone or in-line production setups

Industries & Add-Ons

The Tri-Roller system is perfectly suited for industries demanding precision labelling on round containers, from fast-paced production to artisan-scale operations.

Optional Add-ons

- Encoder for speed following and label positioning

- End-of-roll warning light system

- Thermal inkjet or thermal transfer printer integration

- Barcode and vision system interface

- Reject and missing label detection systems

- Counters for batch tracking

- Sensors for clear and non-transparent label detection

- PLC with HMI touchscreen control

Contact Atwell Labellers

Sales: 01444 239970 | Technical Helpline: 01444 237804

Request a Quote

Use our quick enquiry form to discuss your labelling needs. Our team will recommend the best Tri-roller configuration for your production line.