Beverage Labelling Solutions

Quality beverage label applicators that impact on-the-shelf performance.

Enjoy high throughput rates, superior quality, and consistently excellent results with our bespoke beverage labelling machines.

How We Can Help

Discover more about our Drink label products and services, to see if we have the right solution for you.

Discover Atwell Labellers’ innovative solutions for the drink sector. With decades of experience, we specialise in bespoke precision applicators tailored to meet the unique needs of your business. Our commitment to quality, compliance, and aesthetics ensures your products stand out on the shelf from your competitors. Explore our specialized labelling solutions for different beverage sectors below:

Beer Label Applicators

Labelling your Beer Bottles

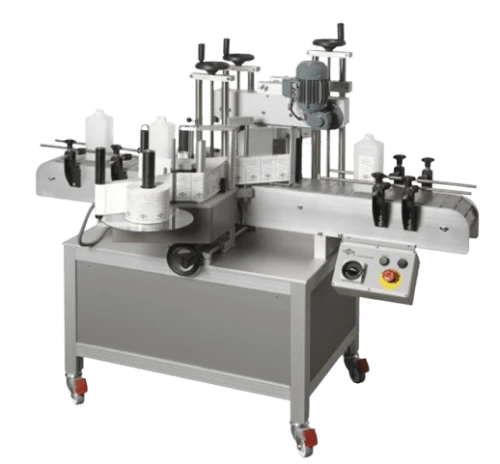

In today’s competitive beer market, automation offers the efficiency and precision needed to stay ahead. Whether you produce beer in bottles or cans, automated beer label applicators ensure consistent quality, increased throughput, and reduced labour costs. The Linear Wraparound is perfect for high volume applications builtin to your current filling line, or if you need to semi-automatically apply labels for that first step towards automation, the Labelease is a great fit.

For growing breweries or those aiming to scale operations, investing in a reliable labelling system is a crucial step. Automated solutions streamline processes, allowing you to focus on what matters most—brewing great beer.

Our machines handle various beer packaging formats, including cans and glass bottles, delivering exceptional label precision and consistency.

Milk Label Applicators

Label Solutions for Milk Bottles and Milk Cartons.

For milk producers, labelling must be efficient, durable, and precise. Atwell Labellers provides solutions tailored to the dairy industry, ensuring smooth integration with your production line.

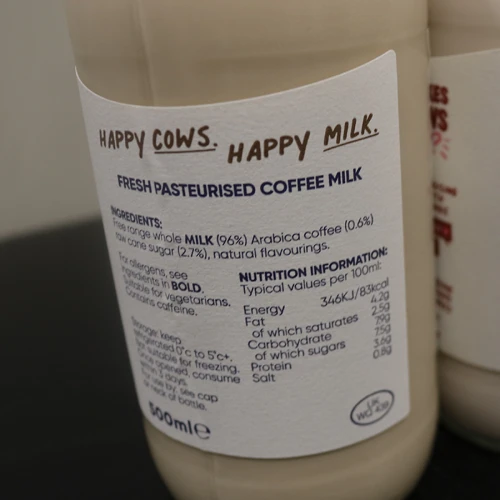

From plastic milk cartons to glass bottles, our systems offer reliable and compliant label application that enhances your product presentation while maintaining operational efficiency.

Accurate and efficient labelling is essential for milk bottles and cartons to ensure compliance, enhance branding, and consumer trust. Atwell Labellers offers bespoke solutions to meet the demands of the dairy industry.

Non-Alcoholic Beverage Applicators

Perfect for Small Artisan Producers.

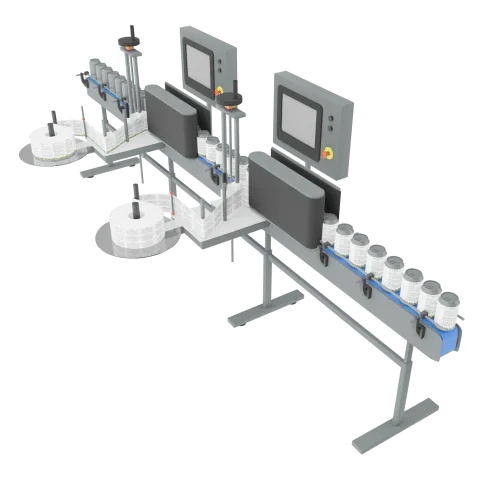

Atwell Labellers offers high-speed, accurate labelling solutions for non-alcoholic beverages, including plastic drink bottles, glass bottles, and cans.

Our machines ensure that your labels not only meet regulatory standards but also enhance the aesthetic appeal of your products. Whether you’re packaging soft drinks, juices, or other non-alcoholic beverages, our systems provide the precision and efficiency your production line needs.

We can help you label your non alcoholic products, regardless of how you store them, including glass, plastic and cans.

Spirit Applicators

For alcoholic and no or low spirit producers.

Precision is key when it comes to spirits. Our bespoke solutions cater to the unique challenges of spirit labelling, from applying intricate designs to achieving perfect label placement.

Enhance your brand identity with high-quality labelling that captures the premium essence of your spirit product. For an example of our expertise, see how we partnered with Ramsbury Brewing & Distillery to create a distinctive side bottle labelling solution.

Whether your spirits are alcoholic or non-alcoholic, we have a solution for you. Each system is tailored to specific needs, ensuring flawless application and alignment with your brand’s unique requirements.

Beverage Labelling Machines Built Exclusively for You

As the UK’s leading independent self-adhesive labelling machine supplier, we’ve served the drink sector for over 35 years.

Here are some examples of custom beverage labelling machines we have installed for our clients:

✓ Can labelling

✓ Glass bottle labelling

✓ Milk bottle labelling

✓ Soft drinks

✓ Alcohol labelling

✓ Case labellers

We build and install bespoke labelling machines based on your unique requirements for optimal results. You tell us your needs, and we’ll do the rest.

Contact us today for advice on the best labelling solutions to help you meet your business goals.

Latest News & Case Studies

Visit Us At EmPack 2026

Visit Us At UK Packaging 2025

Little’s Coffee – Improved Visibility and Security Branding with Atwell Labellers

Want Us to Call You?

If you have any questions about our services or how our services could help you, ask one of our dedicated team of experts to give you a call, just fill out this handy form and we will be right with you.