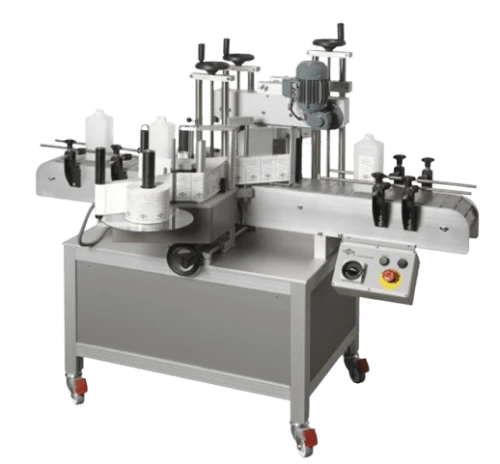

Linear Wraparound Labelling Machine

Linear Wraparound – Automatic Labelling System for Cylindrical or Tapered Containers

The Linear Wraparound delivers precision and flexibility for labelling cylindrical and tapered containers. Built for high-speed efficiency, this system offers smooth integration with production lines or stand-alone operation.

Linear Wraparound

Machine Features

Engineered for adaptability, the Linear Wraparound applies high-quality labels to glass or plastic containers with ease. Its angled label head allows for accurate labelling of tapered products, while tool-free adjustments make changeovers quick and simple.

Max Speed

Up to 150 passes per minute depending on product and label specifications

Angled Label Head

Ideal for partial or full wraparound labelling on tapered containers

Flexible Container Handling

Easily adjust to various diameters using a turnwheel mechanism

Memory Settings

Store up to 25 job settings for repeatable, efficient changeovers

Modular Label Head Sizes

Available in 120mm, 200mm, 250mm, and 300mm web widths, left or right handed

Adjustable Conveyor

82mm+ width and 1.6m+ length with speed control to match production needs

Robust Power & Air Requirements

220/240V AC, 50/60Hz, 600W; clean compressed air, 6 bar max, 8 l/min

Expandable Printing

Compatible with thermal inkjet and thermal transfer printers for batch and variable data

About the Machine

Why Choose the Linear Wraparound?

- Applies both partial and full wraparound labels with precision

- Angled label head ensures accurate application on tapered containers

- Seamlessly integrates with existing lines or functions as a standalone unit

- Adjustable components for quick container size changes

- Expandable with infeed/outfeed tables and a variety of printer options

- Stores up to 25 label jobs for quick and convenient repeatable setup

Industries & Add-Ons

The Linear Wraparound suits industries requiring accurate, high-speed labelling of cylindrical or tapered products, offering expansion options to meet growing production demands.

Linear Wraparound Integration

- Encoder for automatic speed and label position syncing

- End-of-roll alarm and warning light

- Thermal inkjet and thermal transfer printer integration

- Barcode and vision system interface

- Service indicators

- Reject and missing label detection system

- Batch counters

- Sensors for clear and non-transparent labels

- PLC with HMI touchscreen control

Contact Atwell Labellers

Sales: 01444 239970 | Technical Helpline: 01444 237804

Request a Quote

Use our quick enquiry form to discuss your labelling needs. Our team will recommend the best Linear Wrap configuration for your production line.