Food Labelling Solutions

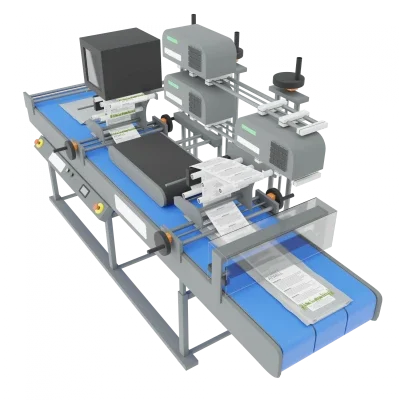

Food label applicator systems for ultimate precision and performance

Labelling is an excellent alternative to traditional sleeve packaging.

How We Can Help

Discover more about our Food labelling machines, to see if we have the right solution for you.

Navigate using the links provided below to find out more about our specific automated food labelling products and solutions available from Atwell Labellers.

We Help You Meet Your Production Goals

Package Labelling Made Easy

If you’re looking for a reliable, efficient, and visually appealing labelling solution, Atwell’s labellers are the ideal choice. By automating the labelling process and providing a more secure, aesthetically pleasing label, these machines can help boost your productivity and enhance your product presentation.

Key Features:

- Maximised Branding Space: A large, continuous label offers ample room for branding and regulatory information.

- Secure Attachment: Ensures labels stay firmly in place during transport and handling.

- Versatility: Adapts to various tray sizes and shapes.

This is ideal for food trays, bakery goods, and similar packaging.

With the added advantage of POLYtij inline thermal inkjet printing, you can easily integrate variable data into your labelling process, ensuring that your products are ready for the market in a timely and professional manner.

Specialist Label Application Solutions

Food Box Label Applicators

These speciality label applicators are designed to fully wrap a label around a product’s tray or punnet, covering the top, sides, and bottom. This method ensures that the label is securely in place, making it ideal for products that require tamper-evident packaging.

Here are just a few of the applications where these labelling systems excel:

• Supermarket Takeaway Boxes: Achieve a professional, tamper-evident seal with full wrap-around labels for pre-packaged meals and takeaways.

• Trays for Meat, Fish, and Poultry: Ensure secure and informative packaging for fresh or frozen meats and seafood, with ample space for nutritional info and cooking instructions with the Top & Bottom Labeller.

• Fresh Produce: Keep fruits and vegetables fresh and well-labelled in punnets or trays with a full D-Wrap label that highlights product origin and other key details.

• Desserts and Food-To-Go: Create appealing, tamper-evident packaging for ready-to-eat products like salads, pastries, or desserts.

Food box labelling is ideal for products that require detailed presentation while maintaining easy product access.

Jar Label Applicators

Our Applicators for Labelling Jars

At Atwell Labellers, we understand the unique challenges that come with jar labelling in the food industry. That’s why we offer two reliable solutions – the Linear Wraparound and the Tri-Roller – designed to keep your production line running smoothly.

Key Features:

- High-Speed Application: Handles up to 150 jars per minute, meeting the needs of large-scale producers.

- Full Wraparound Capability: Ensures labels are applied smoothly and securely.

- Integration Ready: Works with filling and capping machines for streamlined production.

For both artisan and industrial producers, these applicators provide an efficient, high-quality solution to enhance product presentation.

Whether you’re producing small batches or scaling up for larger runs, our labellers are built to help you increase throughput while maintaining accuracy and efficiency. With food labelling regulations evolving, especially around transparency and traceability, our machines ensure you’re ready to meet these changes. Atwell Labellers makes it easier to keep your products compliant, well-packaged, and ready for the shelves.

Produce Bunch Applicators

Labelling Your Produce.

Produce Bunch Applicators specialise in securely labelling fresh produce, such as herb bunches, salad items or vegetables tied together with elastic bands.

Key Features:

- Customised Label Placement: Ensures labels wrap securely around bunches for maximum visibility.

- Durability: Labels remain intact even in moist or refrigerated environments.

- Versatile Configurations: Works with various produce sizes and bunch shapes.

By automating the bunch labelling process, every bunch of produce is accurately labelled, free from human error, and efficiently bundled. This allows your team to focus on more valuable tasks while also improving the overall speed and precision of your production line.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804

Contact by Email:

Latest News & Case Studies

Visit Us At EmPack 2026

Visit Us At UK Packaging 2025

Little’s Coffee – Improved Visibility and Security Branding with Atwell Labellers

You may be interested in

Want Us to Call You?

If you have any questions about our services or how our services could help you, ask one of our dedicated team of experts to give you a call, just fill out this handy form and we will be right with you.