Continuous Inkjet Printing (CIJ) vs. Thermal Inkjet Printing (TIJ): Why TIJ is the Superior Choice

In the world of industrial printing, Continuous Inkjet (CIJ) and Thermal Inkjet (TIJ) printing are two prevalent technologies. Each has its own set of benefits and drawbacks, but for many modern applications, TIJ has emerged as the superior choice. Let’s explore what TIJ and CIJ are, and why TIJ offers a more advantageous solution for today’s printing needs.

What is Thermal Inkjet (TIJ) Printing?

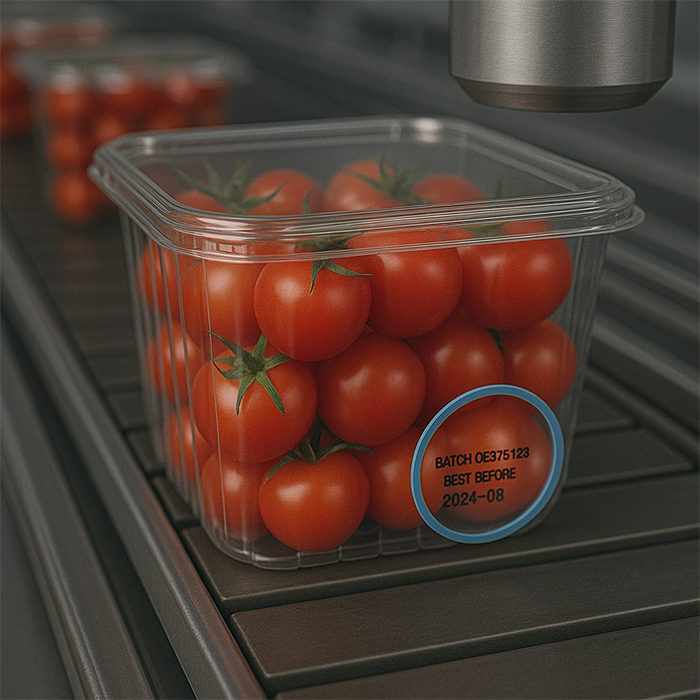

Thermal Inkjet (TIJ) printers use a heat-based mechanism to propel ink droplets onto a surface. This technology enables high-resolution, cost-effective, and maintenance-free printing. TIJ printers do not require direct contact with the printing surface, making them versatile for various applications.

Industries Using TIJ Printers:

- Packaging

- Pharmaceuticals

- Food and Beverage

- Electronics

- Cosmetics

- Chemical

- Production

What is Continuous Inkjet (CIJ) Printing?

Continuous Inkjet (CIJ) printers, on the other hand, utilise a continuous stream of ink that is electrically charged and directed onto a surface. CIJ has been a staple in industrial printing due to its ability to operate at high speeds and print on diverse substrates.

Benefits of Thermal Inkjet (TIJ) Printing

- Polymor Inks: TIJ printers, particularly those from PolyTIJ, use innovative Polymor inks. These inks provide superior performance and reliability, ensuring that prints are high-quality and durable.

- HP Compliant: PolyTIJ printers are HP compliant, which guarantees top-tier printing quality and compatibility with a range of HP ink cartridges.

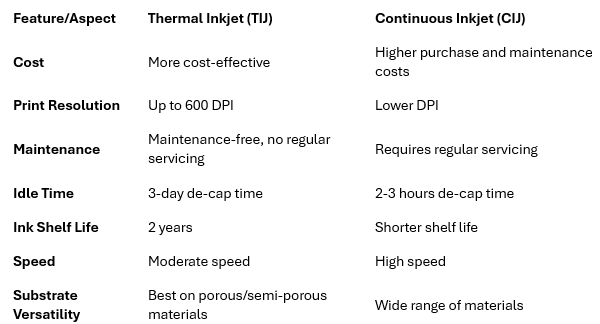

- 3-Day De-Cap Time: TIJ printers can sit idle for up to three days without the ink drying out, compared to the 2-3 hours de-cap time of many competitors. This feature significantly reduces downtime and maintenance needs.

- 2-Year Shelf Life: The inks used in TIJ printers have a two-year shelf life, which helps in reducing waste and overall costs.

Benefits of Continuous Inkjet (CIJ) Printing

- High-Speed Printing: CIJ printers are capable of printing at very high speeds, making them suitable for fast-paced production lines.

- Versatility in Substrates: CIJ technology can print on a wide variety of materials, including non-porous surfaces such as plastics and metals.

- Long-Established Technology: CIJ has been used for decades, meaning it is a well-understood and reliable technology for many industrial applications.

Pitfalls of Continuous Inkjet (CIJ) Printing

- High Costs: CIJ printers are more expensive to purchase and maintain. They require regular servicing every 6-12 months by a trained engineer, adding to the operational costs.

- Lower Print Quality: CIJ systems generally offer lower print resolution (DPI) compared to TIJ printers, making them less suitable for applications requiring fine detail.

- Maintenance Intensive: CIJ printers require more maintenance due to their complex mechanisms, including frequent cleaning to prevent clogs and ensure consistent print quality.

Pitfalls of Thermal Inkjet (TIJ) Printing

- Print Speed: While TIJ printers offer high resolution, their print speed can be slower compared to CIJ, which might be a limitation in extremely high-speed production environments.

- Substrate Limitations: TIJ printers are less versatile when it comes to printing on certain non-porous substrates. They perform best on porous and semi-porous materials.

In conclusion, while CIJ printing has been a reliable choice for many years, the benefits of TIJ printing—especially with the innovative solutions offered by PolyTIJ—make it a more attractive option for a variety of industries. TIJ’s high resolution, cost-effectiveness, and minimal maintenance needs position it as the superior choice for modern printing demands.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804