Industries

Providing quality label applicators to speed up your processes.

We are here to help support product branding, across all of your business.

How We Can Help

Providing quality Applicators and Labels to suit a wide range of industries.

We support a wide variety of industries and packaging types, if you don’t see your industry listed, all of our machines are made bespoke, so they can be tailored to suit your business.

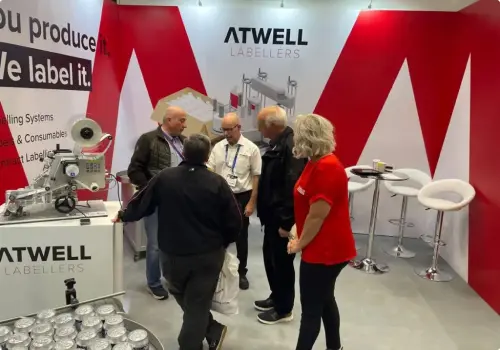

Our Clients

See more examples of our work, and the companies we have worked with on our Case Studies page.

Frequently Asked Questions

Have a question about our labelling applicators or industries we work with. One of these questions and answers might help.

What types of label applicators do Atwell Labellers offer?

Atwell Labellers offers a variety of label applicators including automatic, semi-automatic, and manual models designed for different industries and applications.

How do I choose the right label applicator for my needs?

To choose the right label applicator, consider the type of product, the production speed, the label size, and the environment. Our team can help assess your specific requirements.

Can I get an applicator for my industry?

The simple answer is yes, we serve a wide range of industries including food and beverage, pharmaceuticals, cosmetics, chemicals, and logistics. Can’t find your industry? Don’t worry, just send us an email or give us a call and we can look to make you a applicator bespoke to your needs.

I have a number of different products, does that matter?

Our applicators have a program that can store designs for different products meaning you can have up to 25 different types of products on one applicator.

Can one labelling machine label a range of different products?

Yes. Labelling machines can be made to facilitate a number of product and label combinations, this depends on size and dimensions but our sales team can talk through your requirements and find the solution best for your needs.

You may be interested in

Contact Atwell Labellers

Sales: 01444 239970 | Technical Helpline: 01444 237804

Send Us An Enquiry

Fill in our short enquiry form below, telling us exactly what it is you are looking for help with, and one of our dedicated team will be in touch within 48 hours.

Atwell Self-Adhesive Labellers

Unit 4A Goonvean Business Park

Venn Place

Cullompton

Devon

EX15 1UY