Pet Treat Applicators

Improve your brand perception

Move away from hand-labelling and give your pet treats a premium aesthetic look.

Treat Applicators for all Kinds of Packaging

Discover Our Pet Treat Applicators

If you are looking to move away from hand labelling or looking to increase your production throughput, our range of bespoke pet treat applicators are a great option to consider.

If you have a specific size or shape product and need guidance on what applicator you will need to fit into your production line, you can find some of our most popular pet treat applicators below. If you can’t find what you are looking for feel free to get in touch for an alternative bespoke applicator.

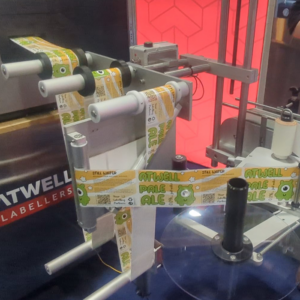

Our Top & Bottom Labellers for Pouch Labelling

Adding labels to your pouched pet treat products with ease.

The top and bottom applicator is an ideal solution for businesses labelling pet treat pouches. Whether you’re working with kraft pouches or plastic featuring clear windows, the system provides precision and flexibility ensuring your packaging stands out on shelves.

Designed for seamless operation, this applicator excels when labelling pouches laid flat, allowing labels to be applied to the top, bottom, or both sides. It’s especially suited for products with unique shapes or varying dimensions, as it effortlessly handles differences in height and weight.

The system supports a range of label sizes, with widths from 120mm to 300mm, and can be paired with the POLYtij thermal inkjet system. This addition enables on-demand printing of batch codes and best-before dates, either directly on the label or the pouch itself, ensuring your customers have the information they need.

For pet treat producers, this labeller guarantees consistently high-quality results. Whether you’re applying branding labels to kraft paper packaging or ingredient labels over plastic windows, the top and bottom applicator is a versatile solution that ensures your packaging meets both branding and regulatory standards.

Semi-Automatic Treat Labelling

For small runs and festive specials, this applicator is perfect.

Whether producing seasonal pet treats or offering custom-label options, the Labelease provides unmatched versatility and ease of use.

If your business involves short runs of pet treats or frequently changing labelling requirements, the Labelease semi-automatic applicator provides the flexibility you need. It allows for on-demand label printing in small quantities and precise application in singles or small batches, making it an ideal choice for smaller suppliers looking to enter the market or diversify their product range. Equipped with advanced sensors that allow for clear and non-transparent labels that ensure consistent application accuracy.

For pet treat businesses aiming to start small or test the waters with new products, this semi-automatic labeller combines flexibility, precision, and user-friendly operation, ensuring your products stand out with professional, high-quality labelling. Additionally, this machine can integrate overprint units, allowing you to add batch numbers, expiration dates, or other critical information directly onto your labels.

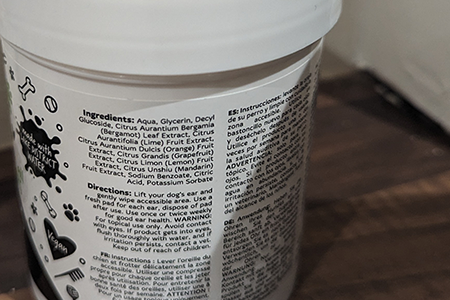

Looking to Label Supplements or Treat Tubs?

Choose the Linear Wrap Applicator.

The linear wrap applicator is an exceptional solution for labelling round tubs of pet treats, whether they are made of plastic or glass. Designed to accommodate products of various sizes, the applicator can be tailored to meet your specific requirements, ensuring precision and reliability in every application.

This applicator offers unmatched efficiency, capable of running at speeds suitable for high-demand production environments, handling up to 150 items per minute. It is user-friendly and requires no prior experience to operate effectively. Its intuitive design is equipped with a PCL and HMI control interface, making adjustments straight forward and enhancing ease of use.

Built for accuracy and speed, the linear wrap labeller keeps your production line moving seamlessly. It supports businesses of all sizes, with conveyor widths starting at 82mm and lengths from 1.6m upwards, adaptable to your needs. Additionally, optional rotary tables (600mm and 900mm diameter) with product separators and bottle dividers make in-feed and out-feed processes more efficient, suiting diverse product types.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804

Contact by Email:

Latest News & Case Studies

What To Look For When Purchasing New Labelling Machines

How Temperature Can Impact Your Label Durability

Dispergo Vaping - Case Study

Want Us to Call You?

If you have any questions about our services or how our services could help you, ask one of our dedicated team of experts to give you a call, just fill out this handy form and we will be right with you.