Jar Labelling Applicators

Applicators for Labelling Jars

Finding the right Applicator for your jar products

Jam Labelling and More

Our Applicators for Labelling Jars

At Atwell Labellers, we understand the unique challenges that come with jar labelling in the food industry. That’s why we offer two reliable solutions – the Linear Wraparound and the Tri-Roller – designed to keep your production line running smoothly.

Whether you’re producing small batches or scaling up for larger runs, our labellers are built to help you increase throughput while maintaining accuracy and efficiency. With food labelling regulations evolving, especially around transparency and traceability, our machines ensure you’re ready to meet these changes. Atwell Labellers makes it easier to keep your products compliant, well-packaged, and ready for the shelves.

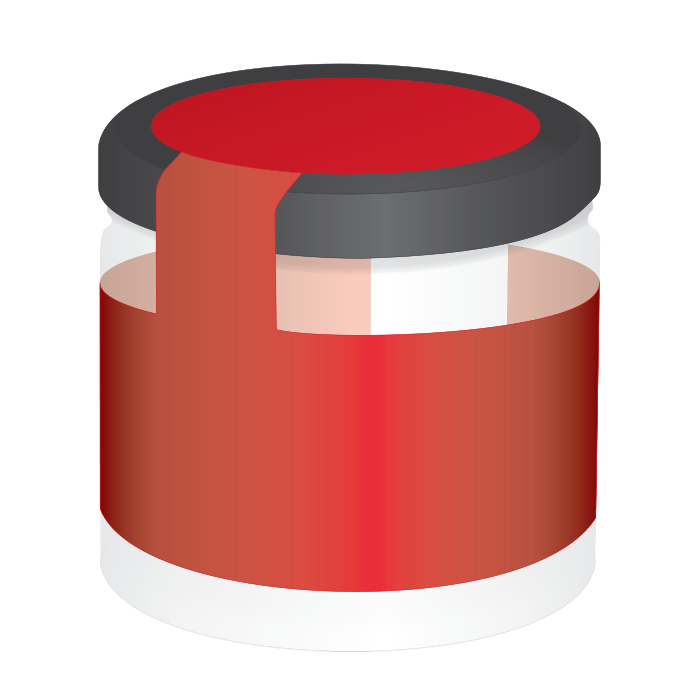

Applying labels with the Tri-Roller

Tri-Roller Applicator

The Tri-Roller Automatic Labeller is an ideal solution for businesses seeking precision and efficiency in jar labelling. This versatile machine accommodates various jar sizes and ensures accurate label placement with its customizable label head options, ranging from 120mm to 300mm web widths. Designed for seamless integration into production lines, the Tri-Roller supports label rolls up to 270mm in diameter and offers optional thermal inkjet or thermal transfer printing, allowing for the inclusion of barcodes, batch numbers, or expiration dates during the labelling process.

With an automatic speed-following encoder and an end-of-roll warning system, it guarantees uninterrupted operation and consistent label application. The Tri-Roller is perfect for industries where consistency, speed, and precision are essential, making it a top choice for jar labelling in sectors like food.

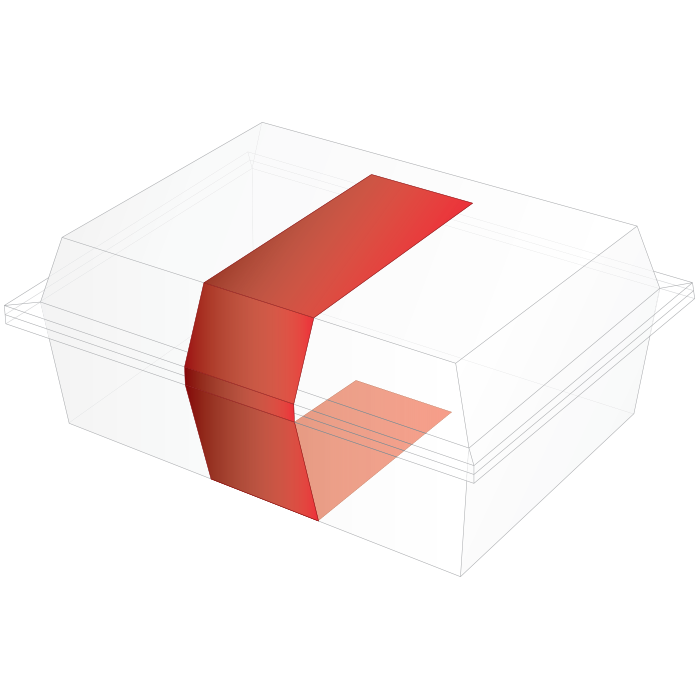

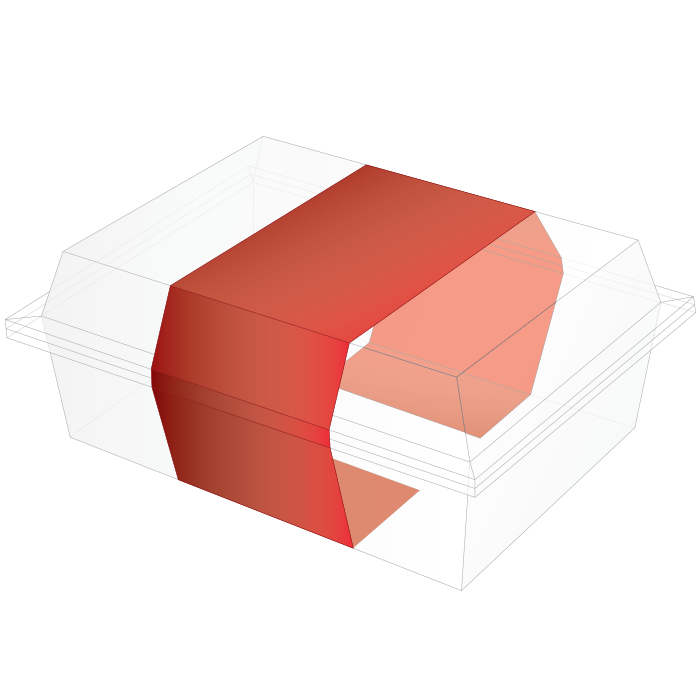

Choose the Linear Wrap for Jar Labelling

The Linear Wrap Applicator

The Linear Wraparound from Atwell Labellers is an efficient and versatile solution for jar labelling, particularly suited for the food industry. Designed to enhance production lines, this machine provides reliable and precise application of labels on jars of varying sizes and shapes. With adjustable label head sizes ranging from 120mm to 300mm, it can accommodate a variety of jar dimensions. The labeller supports both thermal inkjet and thermal transfer printers, enabling high-quality printing of product information, barcodes, and branding on each label.

The Linear Wraparound Labeller is designed for seamless integration into existing production lines, offering customizable conveyor widths and lengths starting at 82mm and 1.6m, respectively. Its maximum label roll capacity is 270mm, ensuring fewer interruptions and longer operational periods between roll changes. The optional rotary tables and product separators further streamline the labelling process, making it highly effective for fast-paced food manufacturing environments.

With features like automatic speed adjustment, an end-of-roll alarm, and a reject system for missing labels, the Linear Wraparound Labeller ensures minimal downtime and accurate labelling with every cycle. This robust and dependable labeller is ideal for businesses seeking a high-performance labelling solution for jars in the food sector, ensuring product packaging is consistent, professional, and compliant with industry standards.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804