Label Applicators for Chemical Products

Chemical label applicator systems for ultimate precision and safety

Meet regulatory requirements and reduce human intervention in an industry where safety is paramount.

Discover more about high quality Chemical label machines and services.

Find the right label applicator for your chemical products.

In Need of a Chemical Container Labelling?

We have an applicator to help you comply with chemical regulations and international standards.

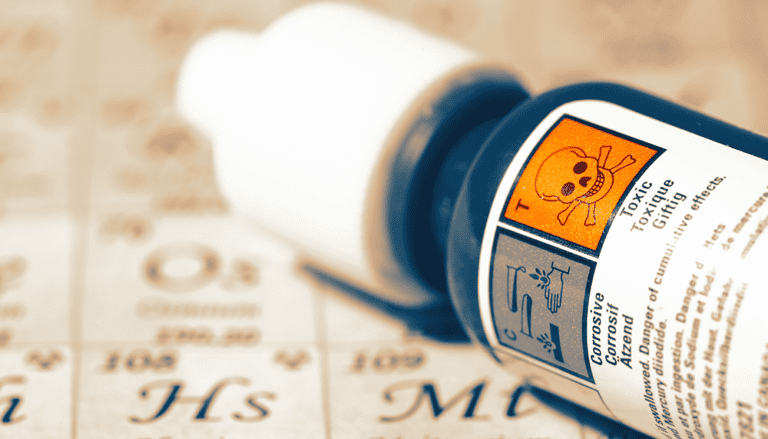

Clear and accurate labelling is crucial for the safety of workers and anyone handling chemical products. Labels can provide essential information about the contents of containers, including hazard warnings, handling instructions, and safety precautions. A label applicator helps ensure that labels are consistently applied with the required information.

That’s why our chemical label applicators are built to address the challenges your chemical related business faces.

Atwell Labellers provides a range of specialised chemical label applicators for bottles, drums, and jerry cans, each engineered to ensure precision, efficiency, and compliance with industry standards. Explore our tailored machinery options designed to meet the unique needs of chemical manufacturers.

Looking to Label Large Chemical Drums?

Drum labelling machinery made easy with the experts.

When it comes to labelling bigger items like drums and buckets used in industrial settings, we’ve got you covered. Our drum labelling applicators are built to manage larger format labels with ease, whether you’re dealing with chemical drums, food-grade containers, or industrial buckets. These applicators keep your production line running smoothly, applying large labels quickly and accurately, so you experience less downtime and more output.

Invest in our drum labelling applicators for a solution that combines efficiency, reliability, and compliance. Reach out to us today to learn how our advanced labelling technology can enhance your production line and ensure your products arrive at their destination labelling to perfection.

Automatic labelling for Jerry Cans

Choosing the right jerry can labelling machine.

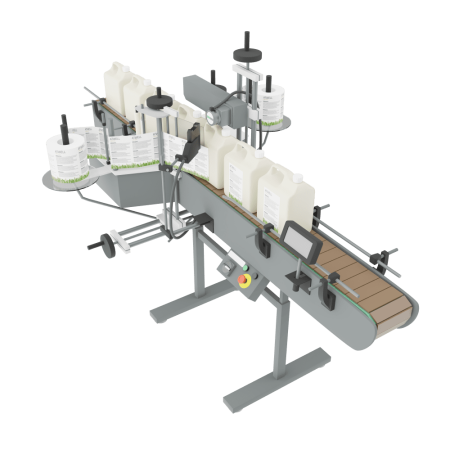

Our jerry can machinery is designed with these principles in mind, ensuring that each chemical label is applied with precision and durability. Here are some key aspects we focus on:

- Accuracy: Every chemical label must be applied correctly to avoid any misidentification of contents. This is especially important when dealing with hazardous chemicals, where the wrong label can have serious consequences. Our machines are built to ensure precision, so each jerry can is correctly identified and handled accordingly.

- Durability: Jerry cans often face harsh conditions, from chemical exposure to rough handling during transportation. Our labels are designed to withstand these challenges, ensuring that they remain legible and securely attached no matter what they’re exposed to.

- Efficiency: In a high-paced production environment, speed is crucial. Our labelling machinery is designed to keep up with the demands of your production line without sacrificing quality, ensuring that your operations run smoothly and efficiently.

- Machine options include the Front & Back Labeller, for automatic labelling of both sides of a jerry can, or the Side Apply if you’re only identifying one side.

Labelling machines for Bottles

Applicators for chemical bottles that keep things simple.

Our chemical bottle label applicators are versatile enough to handle a wide variety of bottle types and sizes. With semi-automatic and fully automatic systems for bottles, Atwell Labellers has a solution for you:

- Small bottles: Ideal for labelling small, often tricky-to-handle bottles typically used in labs and pharmaceutical settings.

- Taller bottles: Engineered to label taller bottles effortlessly, making sure each label is applied evenly and securely.

- Inhibitor bottles: Perfect for bottles containing acetone, solvents, and other volatile chemicals where precision and label durability are crucial.

- Our label applicators are designed to work seamlessly with both glass and plastic bottles, including:

- Glass bottles: Provides a strong adhesive bond and smooth label application, ensuring labels stay put even in tough conditions.

- Plastic bottles: Compatible with various plastic materials such as HDP, PE, and LDPE, offering versatility across different product lines.

Regulatory compliance

Stay compliant with our chemical labelling machinery with ease.

Navigating the Globally Harmonized System (GHS) for the Classification and Labelling of Chemicals is crucial for safety and regulatory compliance. Our drum labelling applicators are designed to help you meet GHS requirements without hassle. We offer a comprehensive GHS labelling guide that walks you through how our solutions ensure your labels include all the necessary hazard symbols, signal words, and precautionary statements. Read all about the GHS regulation here, where we walk you through all the different terms and what is most important when labelling your products.

When it comes to shipping chemicals overseas, compliance with BS5609 regulations is non-negotiable. BS5609 lays out the performance standards for labels used in marine environments, ensuring they can endure harsh conditions like saltwater exposure. Our labelling applicators are built to help you meet these stringent requirements by:

- Ensuring Durability: The labels our machines apply are resistant to abrasion, UV exposure, and harsh chemicals, meeting BS5609 standards.

- Improving Adhesion: Our applicators make sure labels stick securely to drum surfaces, preventing them from peeling or falling off during transit.

- Enhancing Readability: High-quality printing keeps all the information legible throughout the journey.

Are you curious about how adding automation could improve production in your chemical plant? Choose Atwell Labellers to enhance your chemical labelling process with solutions tailored to your production line, supporting both efficiency and compliance across all product types. Contact us today to discover how our advanced applicators can streamline your workflow and uphold safety standards.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804

Contact by Email:

Related News & Case Studies

See us at Fruit Focus 2025

What To Look For When Purchasing New Labelling Machines

Little’s Coffee – Improved Visibility and Security Branding with Atwell Labellers

You may be interested in

Want Us to Call You?

If you have any questions about our services or how our services could help you, ask one of our dedicated team of experts to give you a call, just fill out this handy form and we will be right with you.