4 Tips for Bubble-Free Label Application

When it comes to labelling products or packaging, having the right application method critical. However, one of the biggest challenges many businesses face when it comes to product labels is applying them without getting bubbles. Bubbles not only look unprofessional but can also make the label difficult to read.

There are many reasons why bumps and bubbles appear on product labels, and in order to combat this problem, it’s important to understand what is causing them. Trapped air under the label surface is a common issue when applying labels by hand, but is less of a problem with a label applicator in place. If you are trying to apply labels to a soft material, such as a film or lightweight plastic container, then it can be more challenging to avoid air entrapment as the material gives way under the pressure.

Here are 4 tips from our labelling machine experts for applying clear labels without bubbles:

Clean The Surface Thoroughly

Before applying a label, always make sure the surface of your product packaging is clean, dry, and free from any debris. Dust, oils, or moisture can prevent the adhesive from bonding properly, leading to bubbles or peeling edges.

Use a clean, lint-free cloth and a mild cleaning solution to gently wipe the application area. This applies to both manual labelling and labelling done using machinery — a clean surface is the foundation of successful label application.

Use a Hinge Method For Manual Application

When applying labels by hand, the hinge method is one of the most effective techniques for achieving proper alignment and avoiding bubbles.

To do this, position the label where you want it on the container without removing the backing paper. Use a small strip of masking tape to attach one end of the label to the surface, creating a flexible hinge. Next, lift the label, remove the backing paper while keeping the label taut, and slowly lower it onto the surface. Use a squeegee or your fingers to smooth it out from the hinge end to the opposite edge, pressing out any trapped air.

This method allows for greater accuracy and gives you time to correct alignment before full adhesion occurs.

Apply Even Pressure

Once the label is in position, it’s important to apply consistent pressure across the entire surface. Start at the centre of the label and work outwards to the edges. This technique helps remove any remaining air pockets and ensures the adhesive bonds evenly to the container.

Use a soft squeegee, roller, or simply your fingers to press down gently but firmly. Applying too much pressure too quickly can stretch the label or cause it to wrinkle, especially on curved or uneven surfaces.

Use a Labelling Machine

If you’re labelling a large number of products, manual application can be time-consuming and inconsistent. Investing in a labelling machine allows you to speed up the process while achieving a consistently smooth finish across all products.

Labelling machines come in various configurations — from semi-automatic label applicators to fully automated print-and-apply systems. These machines are designed to apply labels with precision, uniform pressure, and proper alignment, significantly reducing the risk of bubbles or misplacement.

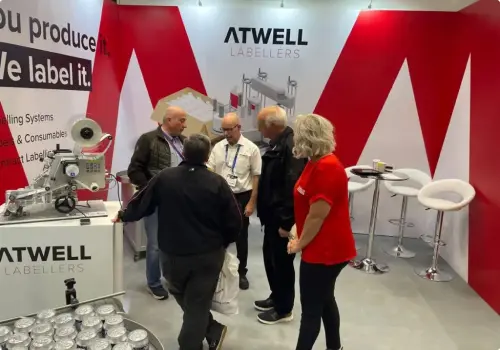

If you’re unsure which type of equipment suits your needs, our team at Atwell Labellers can help you find the perfect solution for your product type, volume, and budget.

Final Thoughts

Whether you’re labelling by hand or automating your production line, taking care with each step of the labelling process ensures your packaging looks professional and lasts as intended. Clean surfaces, accurate alignment, proper pressure, and the right equipment all contribute to a flawless result.

For more advice or to explore our range of labelling machines, get in touch with the experts at Atwell Labellers today. We’re here to help you achieve perfect labelling, every time.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804