Common Labelling Challenges in Manufacturing and How to Overcome Them

For those unfamiliar with the manufacturing world, labelling may seem like an afterthought. In reality, addressing common labelling challenges is crucial in the manufacturing process and can significantly impact whether a product sells or not. Various issues can arise with labelling and the labelling machines in use. To help you tackle some of the most common labelling challenges, we’ve compiled a list of four key issues and how to overcome them.

Tackling Sourcing Problems

Supply chain issues are always a concern, with even the smallest delay having the potential to halt business. Whether it’s a shipping holdup, a printer hiccup, or a paper shortage, you might find yourself unable to label any products. The best way to tackle sourcing problems is to diversify your options. If you have alternatives set up and readily available, you’ll be able to switch over at a moment’s notice when confronted with a major supply chain issue.

Keeping Sustainable

Keeping up with the latest regulations can feel like an uphill battle, especially in a global market. With policies changing frequently, producing labels can become cumbersome and increasingly expensive. If you need to print different labels with various instructions in different languages, costs and waste will quickly pile up. To address this common labelling challenge, many businesses opt to print a single set of labels suitable for all regions, with instructions in multiple languages. This approach keeps costs down and ensures your business remains as sustainable as possible. Find out more about why sustainability matters in contract labelling and labelling equipment.

Keeping Labels Protected and In Place

Most products undergo a rigorous journey before reaching the consumer, and the labels must be robust enough to survive. For example, a bottle of water will experience significant environmental changes before reaching store shelves, moving through various warehouses and cold storage areas, and being bumped around during transport. It’s crucial to pick a label adhesive that can withstand temperature and humidity changes and resist moisture or damage. Most labels need to remain on a product long-term in all manner of environments.

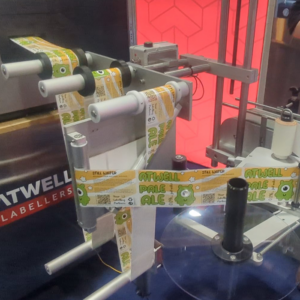

Running a Smooth Production with Top Quality Labelling Machinery

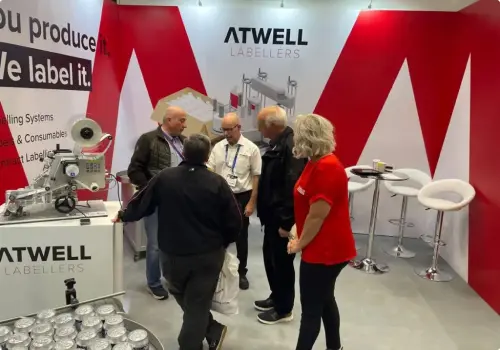

If you’re not using quality labelling machinery, you’re likely already facing issues. A good labelling machine ensures your production runs smoothly, free from breakdowns and costly repairs.

Atwell Labellers has been the country’s leading independent supplier of advanced labelling systems for over 30 years. We know a thing or two about labels and labelling machines. No matter what kind of labelling system your business requires, our team of qualified and experienced experts is ready to help. Contact us today for a free quote, and see how our labelling machines and advanced labelling systems can help you maintain smooth production and overcome common labelling challenges.