3 Reasons To Invest In A New Labelling Machine

Investing in new labelling machinery may seem like a big commitment — especially if your existing machine is still functional. Understandably, most businesses follow a “don’t fix what isn’t broken” mindset when it comes to equipment upgrades. However, even if your current labelling machine is getting the job done, that doesn’t mean it’s doing it in the most cost-effective or efficient way.

Advanced labelling systems have evolved rapidly in recent years, offering enhanced speed, precision, reliability, and user-friendliness. Whether you operate a small production unit or a high-output manufacturing facility, upgrading your labelling equipment could yield significant benefits to your bottom line.

Here are three compelling reasons to invest in a new labelling machine.

New Technology In Labelling Machines

One of the most immediate advantages of upgrading to a new automatic labelling machine is access to modern technology. The latest models are equipped with cutting-edge features such as:

- Intuitive touchscreen interfaces

- Programmable labelling sequences

- Rapid changeovers between product types

- Enhanced integration with production lines and software systems

- Digital label printing capabilities

This technology doesn’t just look impressive — it reduces downtime, improves setup speed, and allows you to operate with fewer manual inputs. In addition, modern digital printing options are often more cost-effective and flexible than traditional methods, making it easier to adapt to short runs, seasonal labels, or variable data printing.

Key benefits:

- Reduced setup and changeover time

- Streamlined operator training

- Lower running and maintenance costs

- Future-proof compatibility with smart factory systems

Improved Precision And Service

Older labelling machines are more susceptible to alignment issues, inconsistency, or slow performance. Manual label application — or outdated semi-automated systems — often leads to crooked labels, air bubbles, and costly human errors.

New automatic labellers are designed to deliver high-precision label placement, ensuring every product looks professionally packaged and complies with any applicable standards or branding guidelines. This is particularly critical for sectors like:

- Pharmaceuticals, where labelling errors can have serious legal implications

- Food & beverage, where clear, consistent presentation impacts buying decisions

- Consumer goods, where branding consistency builds trust

With faster speeds and fewer labelling mistakes, your upgraded system helps you produce more in less time — all while delivering a higher quality result. This translates into shorter lead times, increased customer satisfaction, and improved supply chain reliability.

Key benefits:

- Flawless, consistent label application

- Greater output capacity

- Reduced product rework or waste

- Enhanced brand appearance and shelf presence

Reliable Labelling Machines

As with any industrial equipment, wear and tear is inevitable over time. If your current labelling machine is prone to breakdowns, sensor failures, or feeding issues, it could be costing you more in unplanned downtime and emergency repairs than you realise.

New labelling equipment is not only more reliable but also more efficient to maintain. Upgrading means less time spent troubleshooting and more time spent keeping your production line running at full capacity. With improved durability and the backing of manufacturer support, your risk of costly stoppages decreases significantly.

At Atwell, our labelling machines are supplied with a full 12-month warranty and the option of preventative service contracts, giving you peace of mind that your investment is protected and your operation is covered.

Key benefits:

- Fewer breakdowns and interruptions

- Easier servicing and support availability

- Reduced risk of missing critical delivery deadlines

- Confidence in your production continuity

Is It Time to Upgrade Your Labelling Machinery?

If your current labelling equipment is:

- Slowing down production

- Requiring constant repairs

- Producing inconsistent or error-prone results

- Not compatible with your new packaging requirements

…then it might be time to explore a more advanced solution.

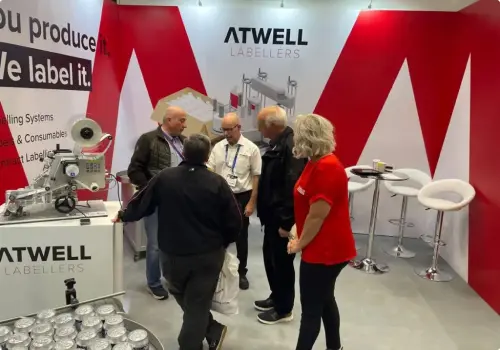

At Atwell Labellers, we supply a wide range of automatic and semi-automatic labelling machines to suit all industries and production scales. Our expert team can assess your needs, recommend the right model, and provide full support from setup to service.

If you are ready to invest in a new labelling machine, get in touch with our team of specialists today.

Can we help you?

Technical Helpline

Contact by Telephone:

+44 (0)1444 237 804