Industries

Providing quality product labels and printing solutions to suit a wide range of industries.

We are here to help support identification, traceability and logistics for businesses across a wide variety of industries.

How We Can Help

Providing quality Product Labels and Printing Solutions to suit a wide range of industries.

We are here to help support identification, traceability and logistics for businesses across a wide variety of industries.

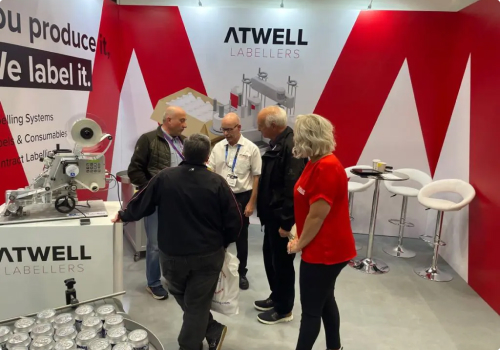

Our Clients

See more examples of our work, and the companies we have worked with on our Case Studies page.

Contact Atwell Labellers

Sales: 01444 239970 | Technical Helpline: 01444 237804

Send Us An Enquiry

Fill in our short enquiry form below, telling us exactly what it is you are looking for help with, and one of our dedicated team will be in touch within 48 hours.

Atwell Self-Adhesive Labellers

18 Bolney Grange Business Park,

Stairbridge Lane, Hickstead,

West Sussex, United Kingdom,

RH17 5PB